Robotic Welding

We specialize in robotically welded precision fabrications

Our core competency of production robotic welding services offer numerous advantages over hand welding, including increased production speeds and efficiency. Since acquiring our first robotic welder in 1990, our staff has grown to become one of the best technical teams in the industry. Mechanical and welding engineers, backed by robotic and programming experts, in conjunction with quality assurance engineers, can provide the total service you need.

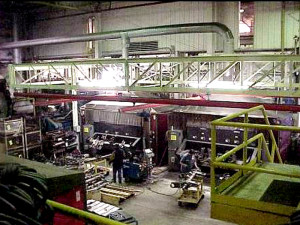

- Our (9) robotic welder cells utilize both single and dual arm configurations and are equipped with a variety of weld positioners, providing flexibility in manufacturing.

- Advanced power supplies provide carefully controlled weld parameters with workhorse reliability.

- Weld fixtures are designed and maintained in-house and all robotic welder programming is done by our experienced technicians to ensure weld accuracy, penetration, and control of tight tolerances.

- Weld cells have ½ ton overhead cranes for handling larger assemblies and allow us the ability to take on challenging configurations in higher volumes. Our robotic welding systems can furnish parts from mere ounces to over 500 lbs. Size Range: Up to 46″ Dia. x 115″ Long.

The competitive advantages of robotic welding and the implementation of lean welding techniques allow for increased throughput while lowering overall fabrication costs. Robotic welding is also more accurate and precise, thus provides better production values across-the-board on the parts we produce for our customers. Give us the opportunity to show you what our robotic welders can do and you’ll become a believer in this technologic advantage as well! We are also expert at providing design suggestions for improving manufacturability and lowering overall production costs. Put our team to work for you!

Request a Robotic Welding Quote Today!

Drive Axle Housing

Drive Axle Housing