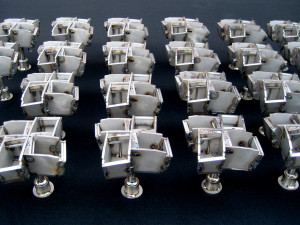

As production of aircraft engine components has increased in sophistication, Rose Metal’s engineering staff has worked closely with customers to design and fabricate each new generation of processing fixturing. Guided by ever present cost restrictions, our design task is to maintain required part support and orientation, create effective masking of portions of the part, facilitate loading / unloading … while optimizing fixture life by reducing distortion at temperature.

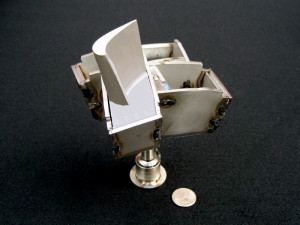

In this case, engine blades are coated at temperatures exceeding 1900 Deg F while exposed to a controlled atmosphere. Fixtures were designed to support / orient each blade for coating of the air foil while masking the root. Careful consideration had to be given to the effects of thermal cycling as well as the coating atmosphere.

In this case, engine blades are coated at temperatures exceeding 1900 Deg F while exposed to a controlled atmosphere. Fixtures were designed to support / orient each blade for coating of the air foil while masking the root. Careful consideration had to be given to the effects of thermal cycling as well as the coating atmosphere.

Product Description – Quad fixture – supporting four blades

Market – Aerospace – Aircraft Engine

Materials – Inconel 601

Size – Aprox 4″ x 4″ x 8″

Processes – Laser cutting, forming, TIG welding, machining

Tolerances – +/- .030″

Inspection – CMM, visual, 100% for parts fit