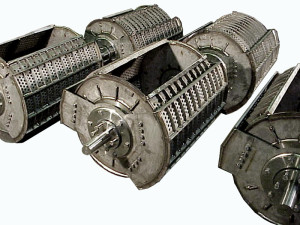

We are a recognized designer and fabricator of carbon steel and alloy process equipment. Shown here are stainless steel rotating (tumbling) barrels with rotating covers which, when installed in the process line are motorized and remotely controlled. Each barrel processes around 1,000 lb. of product per load. In use the barrels and their content are lowered into a variety of tanks for degreasing, washing etching phosphatizing and bonderizing of the barrel contents.

We were originally contacted because our customer was not satisfied with the barrels furnished by a competitor. We were tasked to redesign the barrels which had distorted, preventing the covers from closing properly. Our engineering team’s redesign strengthened the shells and improved the cover construction. We have now produced two generations of the barrels, which are now lasting over 13 years instead of the original 5 to 6.

We were originally contacted because our customer was not satisfied with the barrels furnished by a competitor. We were tasked to redesign the barrels which had distorted, preventing the covers from closing properly. Our engineering team’s redesign strengthened the shells and improved the cover construction. We have now produced two generations of the barrels, which are now lasting over 13 years instead of the original 5 to 6.

Product Description – Stainless Steel Rotating Barrels with moveable covers for loading and unloading

Market – Automotive

Material – Type 316 Stainless Steel

Size – 26” diameter x 34” long

Manufacturing Processes – Punching, laser cutting, machining, rolling and MIG welding

Tolerances – Machining +.000”, – .002” / Fabricating +/- 1/16”

Quantities – Five Barrels per lot

Inspection – Dimensional – conventional instruments, Welds – Visual