Our design team has decades of experience assisting customers to reduce operating costs by increasing the life of thermal processing fixturing. One of the most significant ways to do this is by reduction of distortion caused by the thermal cycle, especially if either gas or liquid quench is involved.

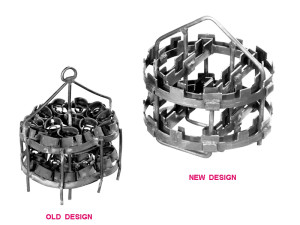

In this case, our customer was experiencing unacceptable fixture life due to warpage of the fixture framework. Our design called for articulation of independent inner rings to support the spheres rather than the rigid circular sockets of the old design. The new fixtures lasted 3.5 times as long as the old design at 85% of the initial cost.

Product Description – Heat Treat Basket for aluminum engine blocks

Market – Thermal Processing

Materials – T330 Stainless Steel

Size – 34″ Diameter x 32″ High

Processes – Material cutting, notching, rolling, MIG welding

Tolerances – +/- .060″

Quantities – 12 pcs per lot

Inspection – Conventional measuring & calipers, visual weld inspection